What Is ERP?

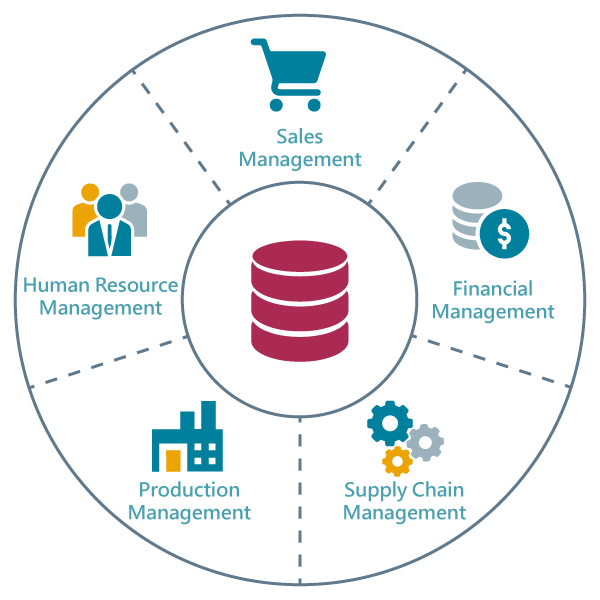

Enterprise Resource Planning (ERP) is a system used to manage an enterprise's daily business activities. It integrates key information such as internal resources, departmental workflows, management practices, and operational processes into a single management platform. By coordinating cross-department collaboration and improving workflows, ERP enables real-time visibility into resource utilization, shortens enterprise response time, accelerates overall business processes, and provides management with critical reference information for operational decision-making. This effectively reduces operating costs and further enhances customer satisfaction.

ERP evolved from Material Requirements Planning (MRP) and Manufacturing Resource Planning (MRP II) as its foundational concepts. It integrates key processes and information across finance, distribution, production, human resources, and supply chain management. Over time, ERP has been widely adopted by global enterprises and has become the core management system for enterprise digitalization and business process reengineering. In recent years, the definition of ERP has expanded to include both internal and external enterprise integration, extending its scope from supply chain management to cross-industry collaboration, with the goal of optimizing overall business processes and jointly achieving profit maximization.

Why Is ERP Important? Why Do Enterprises Need It?

Global demand for ERP continues to grow. According to a report by Grand View Research, Inc, the global ERP systems market is expected to grow at a compound annual growth rate of 11% from 2023 to 2030, reaching USD 123.41 billion by 2030, clearly demonstrating the importance of ERP systems to modern enterprises.

From a practical perspective, ERP systems are important primarily because they help business units manage customer orders, shorten financial closing cycles and ensure timely payments, assist procurement in controlling costs and purchase volumes, enable production management to control quality and production schedules, ensure accurate logistics and on-time deliveries, and support senior executives in obtaining timely information for decision-making. ERP systems provide the most tangible support to all departments within an enterprise.

Four Major Operational Challenges ERP Solves

As enterprises continue to expand in scale, with increasing numbers of employees and more specialized departmental divisions, combined with new business models brought about by digital transformation, issues often arise in operational processes, resource allocation, work efficiency, and costs. Through an ERP system, the following challenges can be addressed:

1. Difficulty in accessing and analyzing financial information:

Corporate finance requires comprehensive collection of transaction data covering the entire process from manufacturing to sales. By leveraging business intelligence analytics, ERP systems accelerate business decision-making, enable organizations to gain accurate visibility into cash flow, reduce manual processing time, and speed up both operations and capital workflows.

2. Untimely and inaccurate inventory management:

As business scale grows, business activities and operational information become increasingly complex. Through automated inventory management, enterprises can easily save time and costs, helping managers retrieve information and make appropriate purchasing or inventory decisions.

3. Difficulty in integrating production information:

Enterprises often encounter a lack of integration across departments, and internal control process improvements are complex, time-consuming, and labor-intensive. ERP systems integrate processes from work order creation through production stages, combined with machine data, to improve operational workflows, ensure operational effectiveness, enforce quality requirements, and provide visibility into critical information at every stage.

4. Procurement efficiency impacted by reliance on manual processes:

Supply chain orders and procurement processes are complex, and reliance on manual operations makes it difficult to fully review orders and supply chain workflows, resulting in wasted human resources. By optimizing procurement and supplier collaboration processes through ERP systems and providing comprehensive reporting and analytics, enterprises can gain visibility into organizational operations, accurately track employee performance, reduce management costs, and resolve performance management and decision-making challenges.

Six Key Benefits of Implementing an ERP System

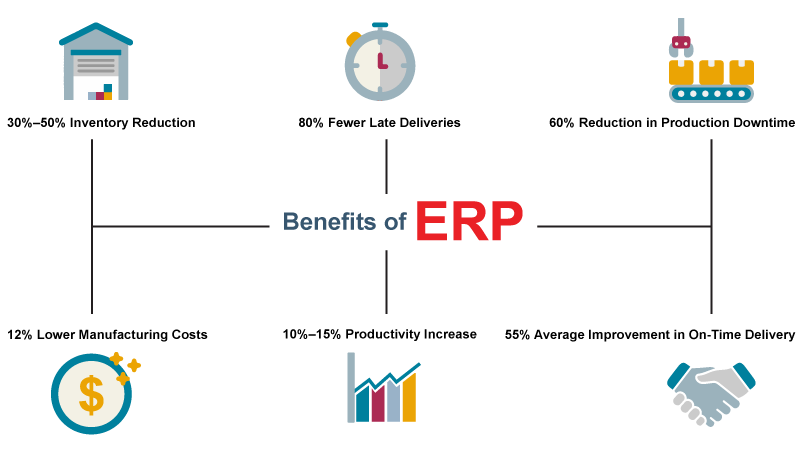

According to statistics from APICS (American Production and Inventory Control Society), implementing an ERP system can deliver the following tangible benefits to enterprises:

| Inventory Levels | Reduced by 30%-50% |

| Late Deliveries | Reduced by 80% |

| Production Downtime | Reduced by 60% |

| Manufacturing Costs | Reduced by 12% |

| Productivity | Increased by 10%-15% |

| On-Time Delivery Rate | Increased by an average of 55% |

ERP systems integrate workflows and information across enterprise functions such as production, distribution, research and development, and financial accounting. Through ERP implementation, enterprises can effectively establish standardized processes, systems, and governance frameworks, reduce repetitive manual operations, and ensure control over TQC (Time, Quality, and Cost). This optimizes operational management mechanisms and ultimately enhances an enterprise's core competitiveness

How to Choose an ERP System:

Differences Between On-Premises and Cloud Deployment

Cloud subscription plans are like renting a house, with annual fees charged and costs adjusted based on the number of employees, the size of the leased space, and changes in licensing rules. Although the initial usage cost is relatively low, as the usage period increases over time, the cumulative cost may not necessarily be cheaper than an on-premises solution. All data is stored and accessed in the cloud service environment, and if the subscription service is terminated, the system can no longer be used.

On-premises system deployment is like buying a house. Product modules are configured and installed on the client side according to requirements. While the initial cost is higher, it provides lifetime licensing with no monthly fees. Oracle ERP implementation offers flexibility in system functionality and operational process adjustments, allowing greater scalability for future operations. It also avoids vendor lock-in through cloud pricing models and provides a high degree of autonomy in system maintenance and operations.

| Evaluation Item | On-Premises ERP | Cloud ERP |

|---|---|---|

| Deployment & Cost | One-time purchase and internal deployment. Higher upfront cost with full hardware and software ownership. | Subscription-based with monthly or annual fees. Lower initial cost. |

| Enterprise Size | Medium to large enterprises with dedicated IT teams, sufficient budgets, and high security and customization needs. | Small enterprises seeking rapid deployment and standardized business processes. |

| Flexibility & Customization | High customization based on business workflows. Strong scalability and system integration capability. | Limited customization. Updates and maintenance handled by the provider. |

| Data Ownership & Control | Enterprise-controlled data with the highest level of security. | Data hosted on provider servers and managed by third parties. |

| System Maintenance & Consulting | Enterprise manages hardware and software. Strong consulting support enables deep customization. | Maintenance handled by the provider. Primarily standardized services. |

| Suitable Industries | Technology, manufacturing, finance, and government sectors requiring complex processes, BOM management, quality control, and regulatory compliance. | Services, retail, e-commerce, startups, and SMEs seeking POS/logistics integration, rapid scalability, and lower upfront costs. |

Three Key Factors for Evaluating ERP Implementation

Successful ERP implementation depends on three key factors: pre-implementation requirements assessment, professional implementation consultants, and a smooth implementation process. By addressing these factors, enterprises can significantly reduce the risk of implementation failure and ensure on-time, successful system go-live.

Key Factor 1: Requirements Assessment

As each enterprise has different requirements and conditions, and given the complexity of ERP system implementation, enterprises are advised to evaluate internal and external influencing factors as well as implementation approaches before proceeding with implementation.

| Internal Influencing Factors |

|---|

| Level of executive support |

| Clarity of implementation objectives |

| Budget |

| Participating personnel and departments |

| Acceptance of change |

| External Influencing Factors |

|---|

| ERP vendor's industry experience |

| ERP vendor's service capabilities |

| Ongoing maintenance of the ERP system |

-

Full-Scale Implementation

The enterprise completely replaces its existing systems and directly implements a full ERP suite, requiring the organization to bear higher risks and costs.

-

Phased (Incremental) Implementation

Implementation begins with a single department. Once operations run smoothly, the system is gradually rolled out to other departments, resulting in lower implementation risk and cost.

-

Modular (Stage-by-Stage) Implementation

The enterprise implements selected functional modules based on current needs, with additional modules introduced later as requirements arise. This approach involves the risk and cost of re-planning in future stages.

Key Factor 2: Consulting Services

In ERP system implementation, consulting services play a critical role in determining whether the system can be successfully deployed. Implementation consultants are not only system functional advisors, but also business consultants. They possess ERP expertise, industry know-how, and hands-on implementation experience. Starting from customer requirements, they help enterprises clarify operational issues and needs, guide clients in applying ERP best practices, and build ERP system applications that align with corporate culture and competitive advantages.

Key Factor 3: Implementation Process

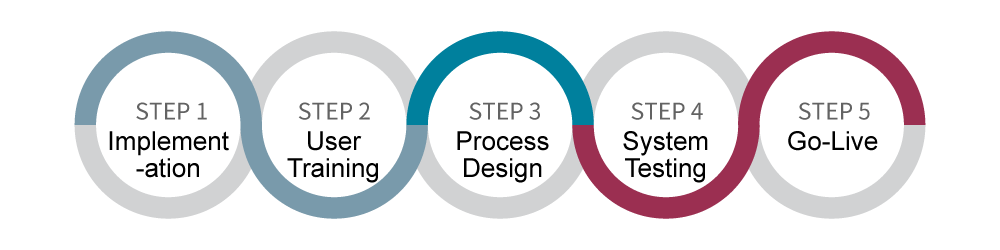

With an experienced ERP consulting team, enterprises can be supported from overall planning and design through a five-phase implementation process. This approach enables step-by-step review and optimization of core business processes, helping enterprises resolve management bottlenecks.

-

Implementation Planning Phase

Project objectives and execution scope are defined by clarifying the enterprise's organizational structure, processes, and requirements.

-

Training Phase

Process prototyping is conducted, and appropriate training programs are designed for different target user groups.

-

Process Design Phase

Consultants and the project team adjust processes based on prototype testing to ensure smoother system operations.

-

System Testing Phase

A comprehensive integration testing plan is carried out, allowing users to perform final integrated testing.

-

Official Go-Live Phase

Ensures on-time system go-live and successful financial closing.

ARES International's Oracle consulting team adopts a stable ARES FLOW implementation methodology, combined with UPK tools to develop online system operation manuals. This approach enables rapid system implementation and training, helping enterprises go live smoothly and quickly become proficient in system usage.

Oracle ERP: The Preferred Choice for Multinational Enterprises

As organizations scale, operational complexity increases. With experienced consulting support and comprehensive finance, distribution, and manufacturing modules, Oracle ERP (EBS) helps enterprises streamline processes and build a solid foundation for digital transformation.